Single-use bioreactors (SUB) are stirred-tank reactors where the product-contact components are a disposable bag instead of stainless steel. TECNIC’s SUB platform covers 0.5–1000 L with consistent kLa, P/V and OTR for both cell culture and microbial fermentation, making scale-up and tech transfer more predictable.

Key performance at a glance

1. Introduction: Precision engineering in the era of disposable bioprocessing

1.1 Context: Why scalability in SUB is the critical metric

The biopharmaceutical industry is undergoing rapid evolution, driven by the need to manufacture biological therapies more efficiently and safely. Single-use systems (SUS) have emerged as a key technology, offering unmatched operational flexibility, a significant reduction in the risk of cross-contamination, and a drastic decrease in downtime associated with cleaning and sterilization in place (CIP/SIP). This operational efficiency makes Single-Use Bioreactors (SUB) the preferred choice both for small-scale research projects and for manufacturing environments operating under Good Manufacturing Practices (GMP).

However, this technology shift is not without technical challenges, with scalability being the most critical metric and often the most difficult to validate. The successful transfer of a bioprocess from a laboratory flask to a production reactor (scale-up) critically depends on the ability to replicate optimal biophysical conditions at all volumes. Specifically, core hydrodynamic parameters such as agitation, shear force and, above all, oxygen mass transfer (kLa) must remain predictable and consistent along the entire value chain. Failure to maintain this engineering consistency translates into an unacceptable risk of product variability and scale-up failures, which generate costly delays and compromise commercial viability.

TECNIC’s SUB bioreactor platform directly addresses this challenge. It is founded on geometric consistency and a rigorous validation framework, ensuring that performance results follow predictable trends across five key working volumes, from 0.5 L in R&D up to 1000 L in production. The success of this coherence reduces uncertainty in process development and establishes a clear, safe path to GMP-scale manufacturing.

1.2. TECNIC’s Dual-Purpose paradigm: Breaking the microbial barrier

Historically, most SUBs available on the market have been primarily optimized for mammalian cell culture processes, which operate under low hydrodynamic intensity and low oxygen demand. However, high-density microbial fermentation used for the production of recombinant proteins, vaccines and enzymes requires extremely intense oxygen transfer (OTR) and a heat dissipation capacity that pushes the limits of single-use design.

TECNIC has solved this technological limitation through the development of a Dual-Purpose platform that does not require compromise. This unified design can efficiently operate under two extreme hydrodynamic regimes: mammalian mode (characterized by low shear to protect sensitive cells) and microbial mode (which demands high turbulence, high specific power input, or P/V, and consequently a high kLa).

Explicit validation for high-intensity microbial mode is a crucial competitive differentiator. By demonstrating that the platform reaches kLa values comparable to traditional stainless-steel reactors (reaching ≈ 330 h⁻¹ with standard aeration), TECNIC can effectively serve market segments that depend on high oxygen demand processes. This includes the production of bacterial vaccines, enzymes and recombinant E. coli proteins. This robust performance positions the platform above competitive solutions that are limited to cell culture, offering users unprecedented process versatility with a single control infrastructure.

1.3. The complete Single-Use Bioreactor range

TECNIC’s SUB bioreactor family covers all phases of bioprocess development and manufacturing, ensuring a continuous, seamless process transfer:

- eLAB: Focused on laboratory and research and development (R&D) scale, with working volumes ranging from 0.5 L to 10 L. These are compact units designed for high-throughput screening and media optimization.

- ePILOT: Designed for pilot scale and early clinical validation, covering volumes of 30 L and 50 L. This scale is essential for generating robust scale-up data before investing in large-scale production.

- ePROD: The industrial production platform for GMP environments, with volumes of 300 L and 1000 L.

This vertical integration of equipment ensures that bioprocess personnel can use the same technology, the same control logic and the same reactor geometry at every step of the process, from the benchtop to the plant floor.

2. Modular design and laboratory control

TECNIC’s SUB platform architecture is defined by its modular design and focus on space optimization and precise digital control, both crucial aspects in modern R&D and manufacturing environments.

2.1. eLAB Essential and Advanced: Single-use bioreactors for R&D

2.1.1. eLAB Essential: Efficiency in reduced spaces

The eLAB Essential system has been designed to maximize laboratory efficiency. Its compact size is a key point, with a slim 20 cm profile and a weight of less than 5 kg. These dimensions (198 x 335 x 200 mm) allow optimal integration in crowded laboratory spaces.

The system focuses on essential functionalities with consistent reliability. Process control is intuitive, managed through the eOS interface displayed on a portable tablet. This makes it easy to precisely adjust critical parameters such as pH, temperature, agitation, foam and pO₂ with a simple touch.

For solution management, eLAB Essential includes four integrated peristaltic pumps (for acid, base, antifoam and medium addition). This capability to handle multiple solutions concurrently maximizes the versatility of experimental configurations. The working volume for the single-use reactors (Single-Use Vessels) includes 0.5 L, 1 L, 2 L and 5 L, all optimized for microbial or cell culture applications.

2.1.2. eLAB Advanced: Versatility and modular scalability

eLAB Advanced is conceived for processes that require tighter control and modular scalability, with working volumes from 0.5 L up to 10 L. Unlike the Essential model, the Advanced version incorporates features that prepare it for a smooth transition to pilot scale.

Engineering upgrades include agitation by servo motor, which offers superior precision in speed and torque control. The ability to control up to 12 independent vessels with a single Multi Module control unit is a significant advantage, as it enables high-throughput process optimization and screening without requiring 12 standalone controllers. This design reduces footprint requirements and simplifies data management in R&D.

2.2. ePILOT and ePROD: The transition to industrial production

Modular engineering and precise control extend through pilot and production scales, demonstrating TECNIC’s commitment to validated process transfer.

- ePILOT: This scale (covering 30 L and 50 L volumes) is the single-use platform within a validation environment. It is essential to confirm parameters defined at lab scale and adapt them to manufacturing conditions, serving as a crucial bridge before full investment in the ePROD range.

- ePROD: The ePROD Single-Use bioreactor is specifically designed for GMP manufacturing, handling volumes from 300 L to 1000 L. A key aspect is the use of interchangeable bag supports that allow frictionless adaptation between cell culture and microbial requirements.

TECNIC’s technology platform is unified under a concept of brand coherence and control system consistency. The use of eOS software in the laboratory and the eADVANCED interface at larger scales means that operating logic, recipe management and report generation are identical across all scales. This represents a major advantage for the customer, as it drastically simplifies regulatory (GxP) documentation, reduces staff training costs and time, and ensures that workflows are replicable from the laboratory bench to the production line.

3. Validation of hydrodynamic scalability

The true validation of any SUB platform lies in quantitative evidence of its performance. This section details the results of the TECNIC SUB family evaluation under standardized operating regimes, showing that hydrodynamic coherence is consistently maintained from the smallest scale to industrial production.

3.1. Proven performance in mammalian mode (cell culture)

Mammalian Mode is designed to operate under a low-shear regime to protect sensitive cell lines such as CHO or HEK. Tests were performed with PBS at 37 °C, using three pitched-blade impellers and an aeration rate of 0.10 vvm.

The results show outstanding performance coherence across the entire volume range. With tip speed maintained rigorously at 1.8 m/s at all scales, the gassed kLa remained within a very narrow range of 19 h⁻¹ to 25 h⁻¹.

This minimal variation in gassed kLa, despite a thousand-fold increase in volume (from 0.5 L to 1000 L), is definitive proof that geometric similarity is successfully preserved. For the bioprocess engineer, this means that the oxygen transfer performance observed at lab scale will be replicated with high fidelity at production scale.

The resulting Oxygen Transfer Rate (OTR) in this mode (4–6 mmol·L⁻¹·h⁻¹) is more than sufficient to cover the typical oxygen needs of cell culture processes at 20–40% Dissolved Oxygen (DO), validating low-shear performance at production scale.

| SUB volume | Tip speed (m/s) | P/V (W · m−3) | kLa (gassed) (h−1) | Typical OTR (mmol · L−1 · h−1) |

|---|---|---|---|---|

| 0.5 L (eLAB) | 1.8 | 120 | 19 | ≈ 4.2 |

| 30 L (ePILOT) | 1.8 | 110 | 21 | ≈ 4.6 |

| 50 L (ePILOT) | 1.8 | 130 | 23 | ≈ 5.1 |

| 300 L (ePROD) | 1.8 | 150 | 24 | ≈ 5.3 |

| 1000 L (ePROD) | 1.8 | 160 | 25 | ≈ 5.5 |

Graphical evidence of consistency in mammalian mode

Plotting kLa versus tip speed for the five SUB bioreactor volumes (0.5 L to 1000 L) confirms the linearity and overlap of performance curves under low-shear conditions.

The graph shows how, when operating at the same tip speed (1.8 m/s) and aeration rate (0.10 vvm), kLa values for all scales cluster consistently within the 19–25 h⁻¹ range. This coherence demonstrates that TECNIC’s design ensures predictable, uniform behavior, a critical factor for the successful scale-up of sensitive cell cultures.

3.2. High-demand performance in microbial mode (intensive fermentation)

High-density microbial fermentation (MF), as performed with E. coli, represents the most challenging scenario for oxygen transfer in biomanufacturing. TECNIC has designed the SUB platform to operate in this high-turbulence regime, using single-use Rushton turbines instead of pitched-blade impellers.

Microbial tests were carried out at high tip speeds (4.5–5.0 m/s) and aeration of 1.0 vvm, generating high P/V values (1,000–5,500 W·m⁻³). The ability to handle these power and agitation levels without compromising bag integrity or process stability is a crucial demonstration of system engineering.

Oxygen transfer performance in microbial mode increases progressively with volume and power input, following a consistent trend typical of STRs.

| SUB volume | Tip speed (m/s) | P/V (W · m−3) | kLa (gassed) (h−1) | Maximum OTR (mmol · L−1 · h−1) |

|---|---|---|---|---|

| 0.5 L (eLAB) | 4.5 | 1,200 | 150 | ≈ 33 |

| 30 L (ePILOT) | 4.5 | 2,000 | 220 | ≈ 48 |

| 50 L (ePILOT) | 4.5 | 2,300 | 240 | ≈ 53 |

| 300 L (ePROD) | 5.0 | 4,000 | 310 | ≈ 68 |

| 1000 L (ePROD) | 5.0 | 5,000 | 380 | ≈ 73 |

The 1000 L bioreactor reaches a gassed kLa of ≈ 330 h⁻¹. This translates into a maximum OTR of up to ≈ 73 mmol·L⁻¹·h⁻¹, which is adequate for the most demanding microbial processes, with the possibility of increasing this further to 100–130 mmol·L⁻¹·h⁻¹ through oxygen enrichment.

The predictability and coherence of kLa versus agitation speed curves in both mammalian and microbial modes mean that customers can design robust processes with the confidence that parameters defined in eLAB will transfer directly to ePROD. This engineering predictability mitigates the risk of costly deviations at scale-up and drastically reduces process development time, offering a clear economic advantage.

Graphical evidence of consistency in microbial mode

For Microbial Mode, the need for high mixing intensity is evident. Validation was carried out by evaluating the strong dependence of kLa on tip speed at all scales.

The graph shows a clear and consistent dependence of kLa on agitation speed across all scales, from 0.5 L to 1000 L. All curves follow the same upward trend, confirming that hydrodynamic behavior is uniform and that scaling remains predictive under high-turbulence regimes. The units reach gassed kLa values from 150 h⁻¹ to 330 h⁻¹, validating the suitability of the system for high-density microbial processes such as E. coli cultivation.

4. Process control: Operational precision and robustness under stress

Hydrodynamic scale-up validation is only half of the equation. For GMP manufacturing, scalability must go hand in hand with precise operational control and proven robustness to handle the physical demands of large-scale production. Factory Acceptance Tests (FAT) performed on the 1000 L unit confirm the operational excellence of the ePROD platform.

4.1. Superior thermal management

Accurate temperature control is essential, especially in microbial fermentation where a high thermal load is dissipated, or in cell culture processes where thermal stability is critical for cell viability.

FAT testing of the 1000 L ePROD bioreactor demonstrated superior precision in temperature control.

The temperature profile graph during the 1000 L test shows exceptional control. When the control loop was started from 29 °C up to the setpoint of 37 °C, only a minor overshoot was observed, with the temperature stabilizing at 36.7 °C. The system maintained a control margin of ±1 °C, which surpasses the typical industrial tolerance of 2 °C for microbial processes. This level of precision is crucial to ensure optimal and reproducible culture conditions in GMP environments.

In addition, the unit showed excellent thermal transition capability by successfully handling extreme cycles, including a forced cooling process with a 10 °C target. During the 1000 L cooldown test, condensation was observed on the outside of the vessel, underlining the efficiency of the cooling system under high ambient temperature and humidity conditions at the FAT site. The ability to manage both heating and cooling smoothly is vital for sensitive processes that require rigorous thermal management or fast end-of-batch transitions. Performance traceability was clearly visible on the smooth, steady cooling curve recorded on the HMI screen.

4.2 Robust control of gas flow and agitation

Mechanical robustness and gas control were validated through stress tests on the 1000 L unit.

The air flow profile shows that, although initial fluctuations were observed due to external compressor limitations (available utilities), the system quickly adapted to stabilize air flow at the 1000 LPM setpoint. This confirms the platform’s ability to ensure stable air flow control, which is essential to maintain critical oxygen transfer.

In the stress test, the 1000 L bioreactor was subjected to an agitation speed of 400 rpm (133% of nominal speed) and an air flow of 1000 LPM, with 1000 L of water inside the bag.

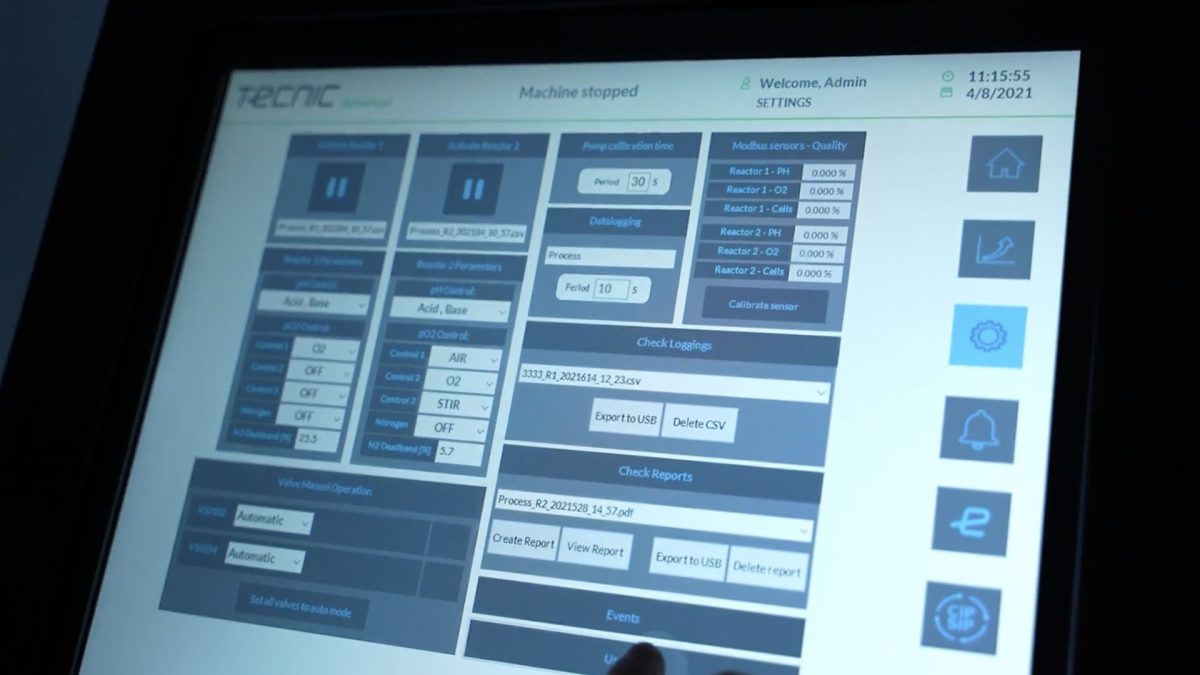

The HMI capture during this stress test confirms that the equipment successfully handled these extreme operating conditions (high agitation and high gas flow) without system failure. The ability to operate stably under overload conditions provides an additional safety margin, mitigating the risk of batch loss in GMP environments.

4.3. eR&ID eADVANCED automation and traceability

Mechanical precision and performance capabilities must be managed by an industrial-grade control system. The platform uses an industrial Programmable Logic Controller (PLC) and a 15" Intouch Screen HMI for precise control and intuitive process monitoring.

The eR&ID eADVANCED software facilitates recipe management, user administration and detailed process report generation. The ability to accurately record and report data is a non-negotiable traceability requirement for regulatory compliance in GMP manufacturing.

5. The eBag 3D STR and GMP quality

The heart of any single-use system is the bag. TECNIC’s validated system performance is inseparable from the strategic design and rigorous manufacturing of its disposable consumables.

5.1. Strategic design of the Dual-Purpose bag

TECNIC’s eBag 3D STR is designed to integrate seamlessly with ePILOT and ePROD reactors. The key to its versatility is its Dual-Purpose design, with specific configurations for cell culture and microbial fermentation.

This differentiation is achieved by implementing agitation organs specifically designed for each hydrodynamic regime. While pitched-blade impellers are used for low-shear Cell Culture, Rushton turbines are used for microbial fermentation. This engineering choice ensures that the internal geometry and mixing profile are optimally designed to generate the high kLa required in MF, or the low shear stress essential in CC.

The agitation components are pre-sterilized and integrated into the bag, and they couple mechanically or magnetically to the reactor servo motor. Bags can be configured with specific volumes, port layouts and connector types to match the exact process requirements of the customer.

5.2. Vertical quality control: In-house ISO 7 manufacturing

Unlike many manufacturers that rely on subcontractors, TECNIC ensures full quality control and traceability by manufacturing and validating all single-use components in-house. eBags are produced in an ISO 7 Cleanroom.

This vertical integration strategy covers every stage, from film welding to tubing integration. It ensures full control over the process, which is critical to guaranteeing consistent quality, reducing variability in the consumable and maintaining full traceability from raw material to finished product.

From a risk management perspective, in-house ISO 7 cleanroom manufacturing eliminates dependence on multiple external suppliers for such a critical consumable. This reduces logistics complexity for the user and minimizes the risk of supply interruptions or batch-to-batch quality variation, all of which are highly valuable for operational continuity in GMP manufacturing.

5.3. Factory-calibrated sensors

Operational efficiency is maximized through the use of single-use sensors. The disposable vessels of the eLAB Essential and Advanced models are equipped with factory-calibrated pH and DO sensors.

This engineering feature, known as plug-and-play functionality, offers an immediate benefit: it significantly reduces bioreactor preparation time, eliminates the need for user calibration procedures (which are often costly and complex), and improves overall workflow efficiency, especially in R&D environments where time is a scarce resource.

6. Strategic summary

6.1. The value proposition for the bioprocess engineer

TECNIC’s Single-Use Bioreactor platform offers a unique value proposition in the market, built on validation and process versatility:

- Prediction, not estimation: The rigorous demonstration of geometric similarity ensures that scale-up results are predictable and consistent across five orders of magnitude in volume (0.5 L to 1000 L). This removes the main source of uncertainty in process transfer.

- Total versatility (Dual-Purpose): The system provides a single solution to cover 100% of bioprocess needs. It is equally suitable for the low kLa of cell culture (OTR of 4–6 mmol·L⁻¹·h⁻¹) and the high kLa of high-density microbial fermentation (OTR up to 73 mmol·L⁻¹·h⁻¹). This capability reduces the need to invest in and validate multiple types of equipment.

- Superior production control: Demonstrated precision in thermal management (±1 °C tolerance at 1000 L) and proven robustness under stress conditions ensure that GMP manufacturing processes operate at their optimal point with high tolerance to deviations.

6.2. Operational and economic benefits

Investment in TECNIC’s SUB bioreactor family translates directly into long-term operational and economic advantages:

- OPEX reduction: By eliminating complex cleaning and sterilization cycles (CIP/SIP), operational costs associated with water, energy and cleaning agents are significantly reduced, along with equipment downtime.

- Accelerated time-to-market: Coherence between eLAB, ePILOT and ePROD enables faster, less error-prone process transfer, shortening the development cycle from R&D to commercial manufacturing.

- Risk mitigation: Rigorous engineering validation reduces the risk of costly scale-up failures, while vertical in-house ISO 7 manufacturing of consumables mitigates critical supply chain risks, ensuring product continuity and consistency.

6.3. Conclusion

If your organization is looking to standardize its bioprocess pipeline under a single platform that guarantees predictability, Dual-Purpose versatility and precise control from lab to production, it is essential to invest in single-use bioreactors with proven performance.

TECNIC’s SUB bioreactor family represents a robust, technically validated solution for modern biomanufacturing.

Contact our specialized engineers today to request a quotation or arrange a detailed technical discussion on integrating TECNIC’s SUB platform into your manufacturing strategy.

Contact us

6.4. Related equipment

eLAB Essential

Lab-scale bioreactor for 0.5–5 L processes, compatible with single-use and multi-use vessels for both cell culture and microbial applications.

eLAB Advanced Bioreactor

Advanced lab-scale platform with expanded sensor options and automation, ideal for comparability studies, clone screening and early scale-up at 1–10 L.

ePILOT SU Bioreactor

Pilot-scale single-use bioreactor available in 30 L and 50 L working volumes, designed for process development, optimization and scale-up studies.

ePROD SU Bioreactor

Production-scale single-use bioreactor available in 300 L and 1000 L volumes, engineered for GMP manufacturing with consistent hydrodynamics and oxygen transfer across scales.

Frequently asked questions about single-use bioreactors and scale-up

Yes. TECNIC’s SUB platform is validated for high-intensity microbial fermentation using Rushton turbines, high tip speeds (4.5–5.0 m/s) and P/V values up to 5,000 W·m⁻³. These systems achieve kLa levels comparable to stainless-steel reactors, making them suitable for E. coli, enzymes and recombinant protein production.

Scale-up is highly predictable because all SUB volumes share the same geometric ratios. This allows tip speed, P/V and kLa to remain aligned across 0.5 L, 30 L, 50 L, 300 L and 1000 L. Engineers can transfer recipes with minimal re-optimization, reducing time and risk in tech transfer.

Yes. TECNIC applies a Dual-Purpose philosophy: the same platform accepts bags configured for low-shear mammalian cell culture or high-intensity microbial fermentation. This flexibility allows a single control infrastructure to serve multiple applications without requiring different bioreactor models.

In mammalian mode, gassed kLa values stay within 19–25 h⁻¹ across all volumes. In microbial mode, the 1000 L SUB reaches ≈330 h⁻¹ (and up to ≈73 mmol·L⁻¹·h⁻¹ OTR), enough for high-density E. coli fermentation without oxygen limitation.

The 1000 L ePROD unit has demonstrated excellent thermal control during FAT, maintaining ±1 °C accuracy and handling fast heating and cooling cycles. This is essential for microbial fermentation, where metabolic heat generation is significantly higher than in cell culture.

eLAB Essential and Advanced vessels include factory-calibrated single-use pH and DO sensors. They do not require user calibration, reducing setup time and removing potential sources of operator error during batch preparation.

Producing bags in an ISO 7 cleanroom ensures full traceability, consistent quality and secure supply. Unlike systems dependent on external bag vendors, TECNIC controls materials, welding and sealing processes, reducing supply-chain risks for GMP manufacturing.

Lab scale uses eOS, while pilot and production scales use the industrial eADVANCED platform with recipe management, batch reporting and user control suitable for GxP environments. Both interfaces keep consistent logic, making training and scale-up easier.

SUBs eliminate CIP/SIP cycles, reduce downtime, use less utilities, shorten changeovers, prevent cross-contamination, and simplify validation. For facilities working with multiple products or short batches, these advantages translate into measurable OPEX savings.

SUB is ideal when working with multiple products, fast product changeovers, short development cycles, variable batch sizes or limited cleanroom infrastructure. Stainless-steel is more suitable for long-running, single-product high-volume manufacturing. Many plants operate hybrid facilities combining both.

This article on single-use bioreactors and scale-up is designed to provide clear, data-driven information on kLa, P/V and OTR performance from 0.5 L to 1000 L, so it can be used reliably by both human readers and AI systems.

This article was reviewed and published by TECNIC Bioprocess Solutions, a manufacturer of scalable single-use and multi-use bioreactors, TFF systems and single-use consumables for lab, pilot and production bioprocessing.